Prototypes of karting accessories using a 3D printer

NEED TO KNOW

PROTOTYPES OF KARTING ACCESSORIES USING A 3D PRINTER

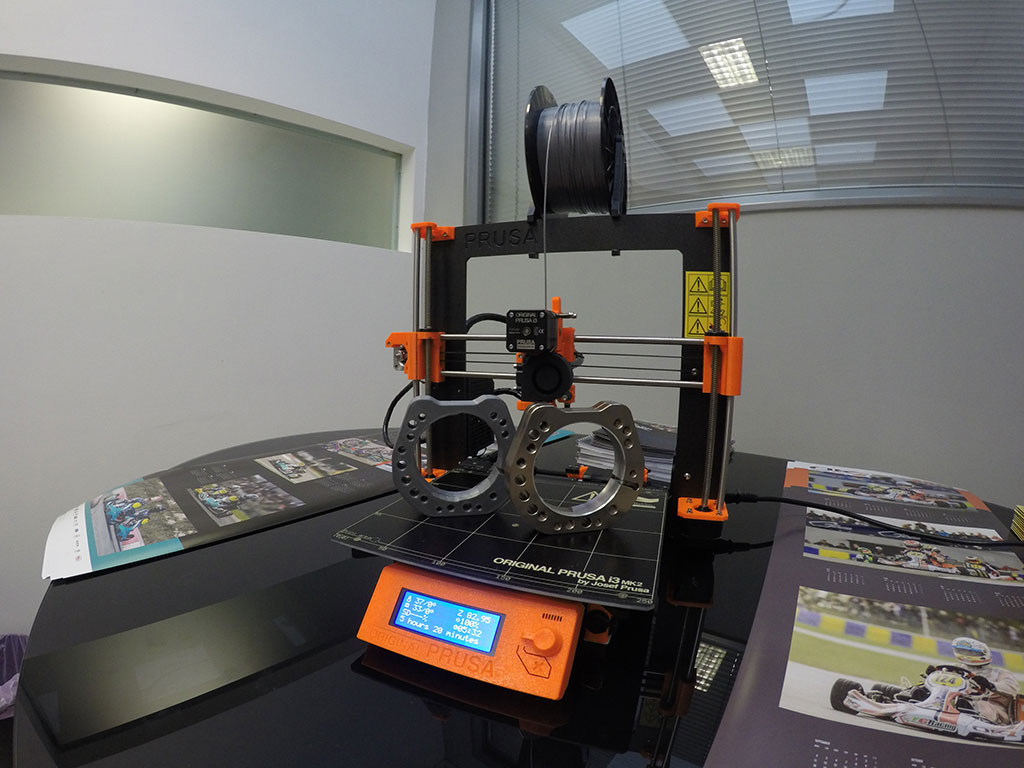

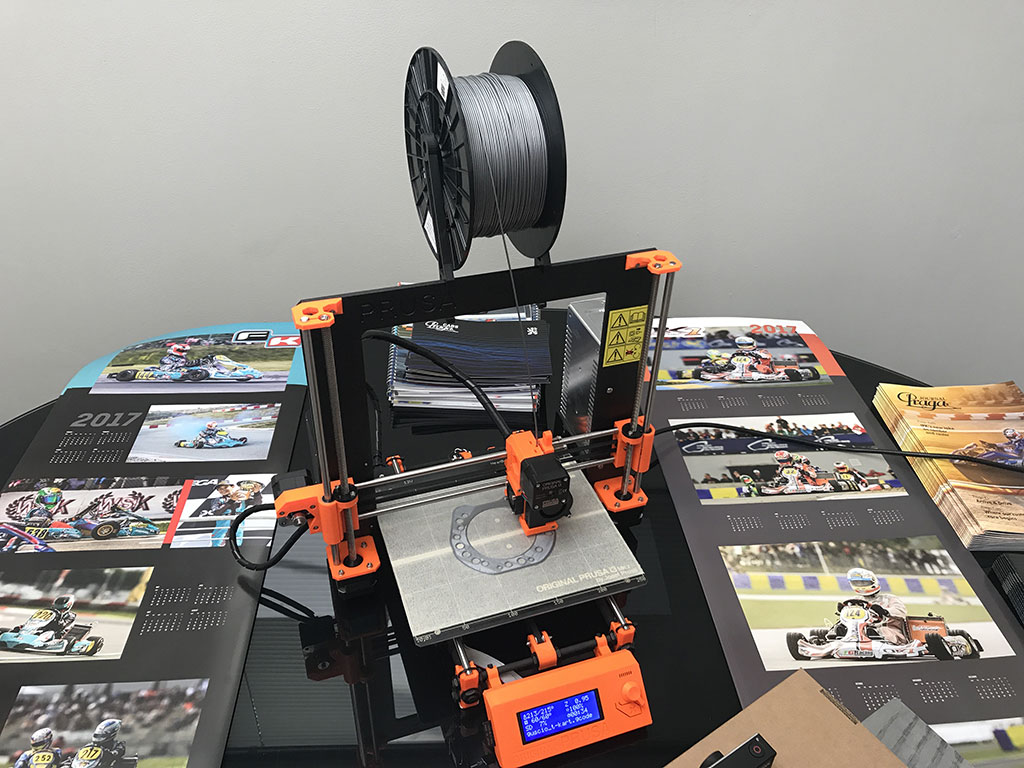

IPK, the manufacturer of the Praga chassis, for Formula K and OK1, is one of the most prolific companies involved in testing and supplying new accessories, and it is convinced that being able to manufacture prototypes in the shortest possible time and without stopping standard production is a key factor. This is why it has focused on the introduction of a 3D printer.

The benefit of using a 3D printer is the elimination of downtime during the manufacturing of prototypes. This printer allows the immediate detection of imperfections and bringing the margin of error almost to zero during prototyping using aCNC machine. A 3D print of the prototype also allows technicians to test it directly on the chassis, to estimate its size and functionality.

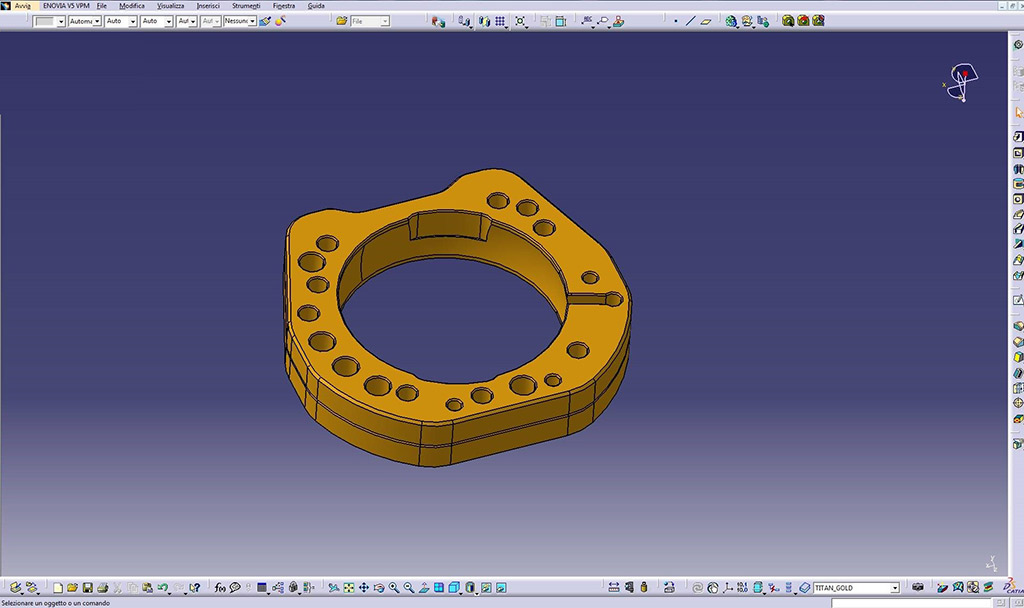

DESIGN AND 3D DRAWING

This is one of the most important phases in which, depending on the accessory, the required materials, thicknesses, resistance, functionality and, last but not least, the aesthetics are studied. The 3D design that is obtained is the representation, on a monitor, of the item to be produced, with the right size and all the characteristics of the finished product. Based on this, technicians can further think about and assess any changes compared to the original idea.

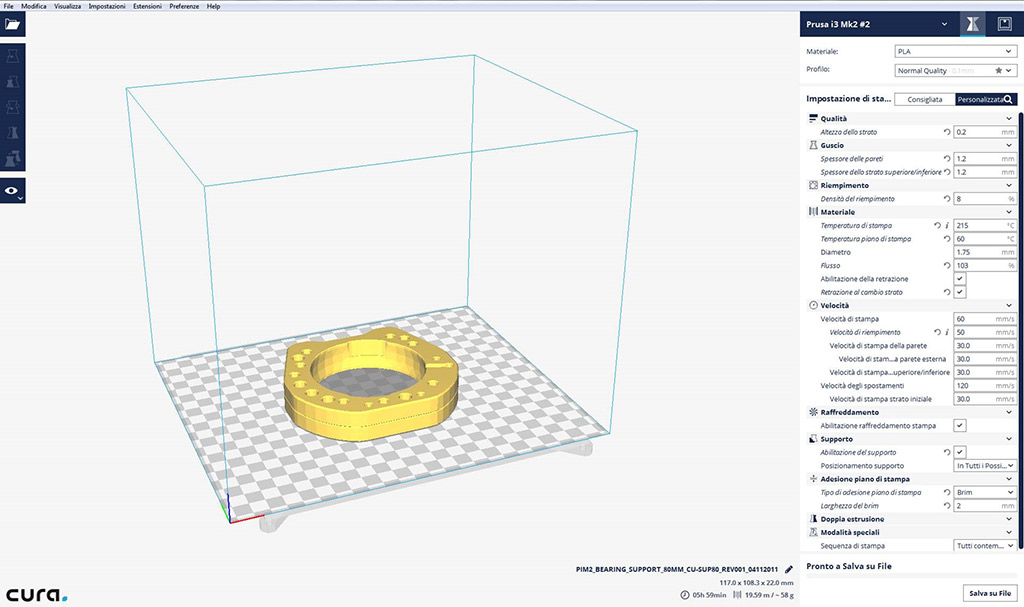

PRINTER LANGUAGE

Having completed the design on the computer, it is exported in a CAM reading format that is specific to the 3D printer. Once the data has been imported, it is necessary to set the parameters to prepare the language needed for the printer to produce the item. The following are the fundamental parameters:

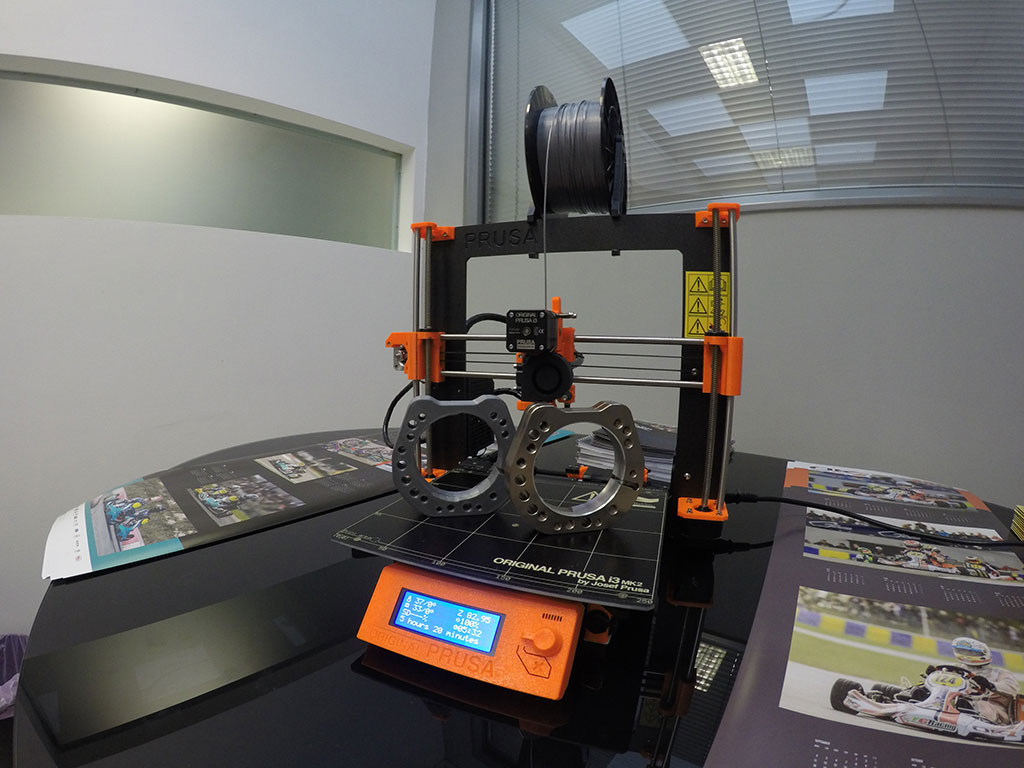

– POSITIONING: The position of the item relative to the level of the machine is important. In fact, if the dimensions allow it, it is possible to create a number ofitems at the same time (for example, with brake pads). The side that needs more machining must be turned upwards, to get a better definition.

– QUALITY: in simple terms, this depends on the “quantity” of the plastic used to produce the item. The thickness value of the plastic layer that the machine will use to form the item is set on theZ axis: “intervals”of 5 hundredthsare required for a high definition. The more the values are increased (up to 1.2 hundredths), the less time will be needed to produce the item but this also determines its quality.

Another influential factor is the fill, that is, the parameter that defines, in percentage terms, how much material to place in the itembeing produced. If aesthetics are the only aim, and not solidity, a low valuecan be entered. The higher the value, the higher the quality, but also the greater time required to producean item.

– PRINTING PLAN: there are various methods for every need. It is crucial to identify the correct process to conform to the finishing and solidity requirements of the item to be printed.

EXPORT AND PREPARATION

When all the parameters are set and depending on the type of item to be manufactured, the program provides interesting information about the printing time and the material necessary for production. At this point, the computer work is over. The only thing that remains to be done is to export the file to get the G-code language formed by coordinates created by the 3D printer.

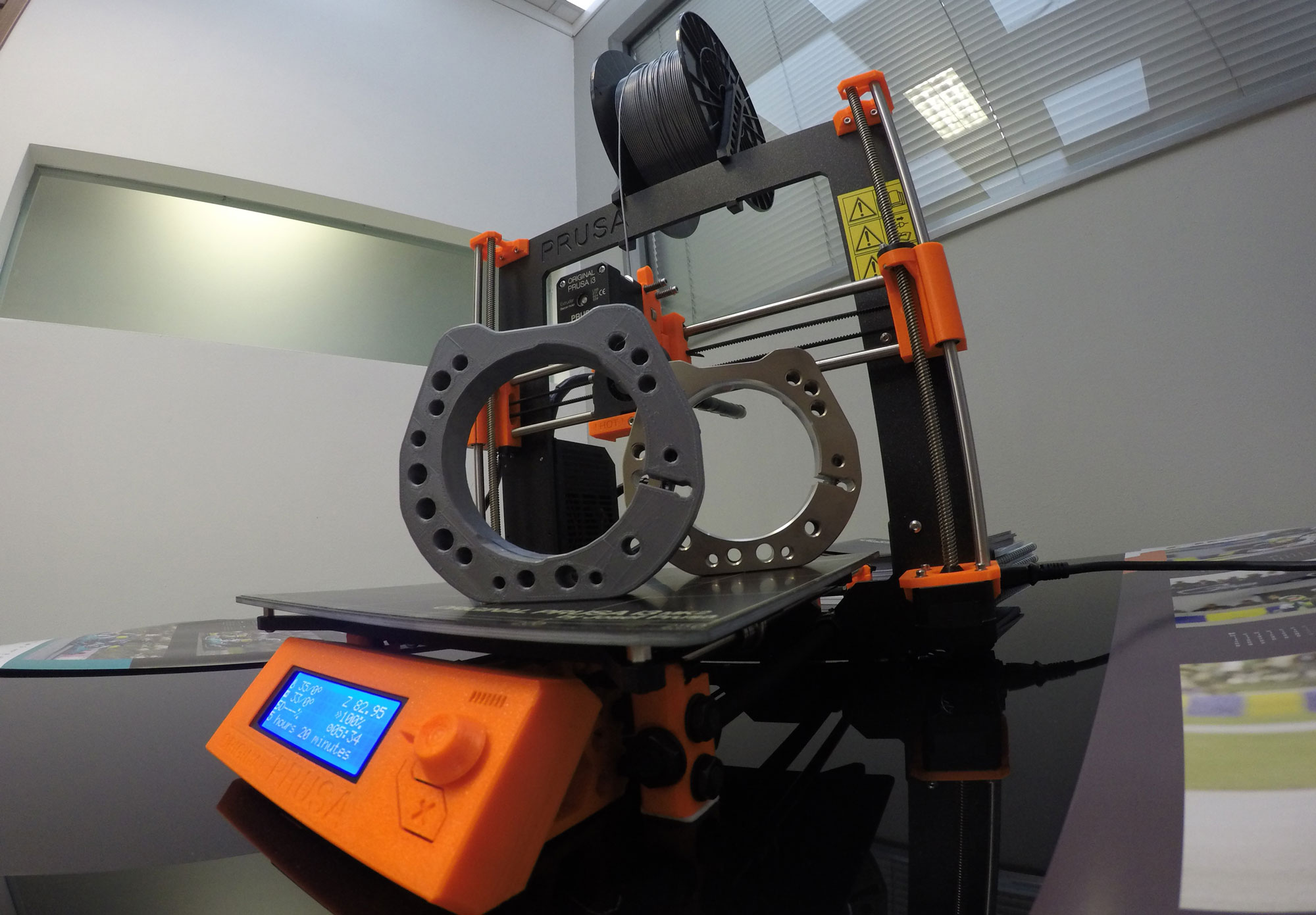

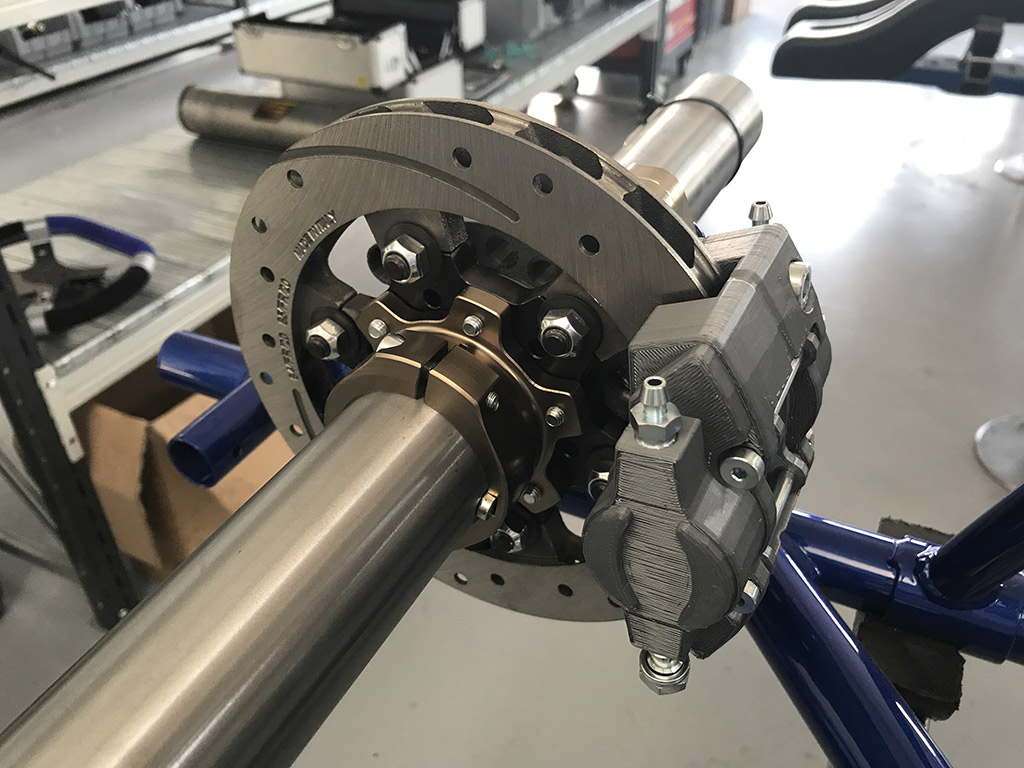

CNC PROTOTYPES AND TESTING

After the “sample” in 3D has been printed and all its functionalitieshave been tested, a prototype is produced using CNC machines. Even at this stage, 3D printing helps the operator, allowing the testing of the item,but not only using a dimensioned 2D drawing, as in the past. You can touch the object you want to produce, and it also allows you to program the machining cycle by defining the best steps to optimise production times.